When Boutsady Muongkhot went to get tested for COVID-19, he didn’t feel sick. His daughter had told him to do it. Muongkhot, who is seventy-one, is the youngest of ten children born in a farming village in Laos, and one of two brothers who came to the United States. He is just over five feet tall—wiry and gregarious—and speaks Laotian, Thai, and French, in addition to English, which he learned in Texas. His accent lands somewhere in between—part fourth-language hesitancy, part drawl. By the time COVID-19 reached the Texas Panhandle, where Muongkhot had spent nearly four decades of his life cutting meat, he had retired. His wife, however, still worked at the Tyson meatpacking plant in Amarillo. His daughter had warned him about the pandemic. He had watched the news. But, for all his concern, Muongkhot had been lax in his home. “I know they say on the TV cover your nose, cover your face every time you go out of the house,” he told me. “But I forgot to think about my wife.”

This was the first wave of the virus in Texas, centered on the meatpacking plants that run north from Amarillo toward Oklahoma. Each plant, in the early months of the pandemic, represented both a concentrated outbreak and an amplification of the problems that have become familiar across the United States: the confusion of messaging, the conflict between life and commerce, the conspiracy theories and the outright denial. Unless you were there, on the front lines, in the hospitals or in the hardest-hit communities, it all seemed invisible and abstract.

As a result, Muongkhot had found himself in the middle of one of the first big outbreaks in Texas without realizing it. Amarillo, a city of around two hundred thousand people, sits at the intersection of two counties—Randall and Potter—with most of the immigrant population situated in Potter. As of July 1st, seventy-seven per cent of the city’s thirty-seven hundred cases have come out of Potter. In Moore County, to the north, the site of another large meatpacking plant, at least one in every twenty-five people have contracted the disease—a rate equivalent to the hardest-hit neighborhoods in New York City. As early as February, Muongkhot’s wife had heard rumors. There were people who had gone home sick, but it might have been the flu. “The company keeps running and running,” Muongkhot said. “I didn’t think my wife would get the virus and then connect to me. We were like regular people having a regular time together.”

No one knows when the coronavirus first arrived in the Panhandle’s meatpacking plants. The first recorded case in Amarillo, on March 18th, had nothing to do with the plants; it involved someone travelling for a basketball game. But, by the time Muongkhot went to get tested, in May, local hospitals had been seeing infected workers for weeks. And the people that were coming in, health-care workers suspected, were just the tip of the iceberg. Meatpacking plants are perfectly suited to aid the transmission of any virus (an Amarillo doctor who specializes in tuberculosis said that he sees about fifteen TB cases every year), and COVID-19 spreads more quickly than the flu. People on the lines work shoulder to shoulder. The air is kept cold. It is too noisy to hear someone cough, noisy enough that people regularly shout in one another’s faces. And, in rural towns like Cactus (which Waylon Jennings described as a “wide place in the road”), many workers were getting driven back and forth to plants in packed vans.

“As soon as they were talking about the pandemic, we all knew that it was only a matter of time,” Rodney Young, the chair of the Department of Family and Community Medicine at Texas Tech School of Medicine in Amarillo, told me. In China, when the pandemic surged in January, meatpacking plants across the country were shut down for weeks. In Nebraska, an emergency-room doctor sent an e-mail to the regional health department warning about an outbreak at a local JBS plant on March 31st. Daniela Dwyer, a lawyer with Texas RioGrande Legal Aid, said the agricultural sector was a concern from the beginning—advocates wrote a letter, dated March 25th, to Mike Pompeo addressing the vulnerability of temporary agricultural workers in particular. “I think everybody who works with low-wage workers and workers in agriculture knew that this was going to become an issue,” she said.

And yet, on April 12th, when an outbreak forced the closure of a Smithfield pork-processing plant in North Dakota, which is responsible for five per cent of U.S. pork production, it took officials and workers by surprise. Cargill had already shuttered a plant in Pennsylvania, on April 7th, and other meatpacking plants were soon shutting down across the nation. On April 15th, a JBS plant closed in Greeley, Colorado, and another JBS plant closed in Worthington, Minnesota five days later. By April 22nd, more than a dozen plants had been closed, and at least twenty-two hundred workers, from forty-one plants across the country, were infected. But the two largest plants in the Panhandle—one owned by JBS, the other by Tyson, which together employ about seven thousand workers—kept running.

As OSHA and the C.D.C. scrambled to come up with workplace protocols, the alarm about the outbreak was matched by dire warnings of a breakdown in U.S. food supply chains. Even as workers grew ill, the U.S. Department of Agriculture was relaxing safety oversight, allowing fifteen poultry plants to exceed guidelines on how many birds workers could process in a minute (more waivers than had ever before been given in a single month). And then, on April 26th, John H. Tyson took out full page ads in the New York Times and Washington Post warning that the “food supply chain is breaking.” Two days later, Donald Trump announced that meatpacking plants were considered essential businesses. No matter what, the plants had to stay open. The rest of the world was distanced, but workers had to keep coming in.

Muongkhot has been in Amarillo for forty years. His entire life has been subject to the rhythms of work at Tyson. When he first arrived, he made $2.65 an hour fixing car speakers; he found cutting meat paid more, $4.84 an hour. As time went on, the salary went up until he was making thirteen dollars an hour. His wife is still cutting, he explained, because she is twenty years younger. “I have been married twice,” Muongkhot said. “I went back to Laos to meet her, and I just tell the truth.” The snow, the plants, and his three children. “I don’t have no education,” he said. “I just cut meat, cut meat, cut meat.” He worked on the production floor. He worked sharpening knives or managing the freezers. At first, the people in Amarillo were not welcoming. He made money and bought a Trans Am. His neighbors threw eggs and sometimes rocks at his new car. But more refugees kept coming.

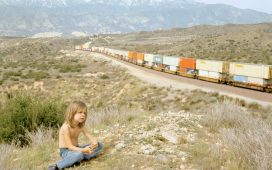

Since a wave of immigration raids, in 2006, meatpacking plants around the nation have increasingly relied on a workforce of refugees. They have changed the face of rural America, creating communities within communities. In the Panhandle, populations of the Karen people from Myanmar rub elbows with refugees from Laos, the Democratic Republic of Congo, and Somalia. Altogether, more than twenty different languages are spoken at the plants and in the community. Meatpacking plants are famous for their difficult working conditions—long days standing close together wielding saws and knives—and it is hard to keep enough staff on the line to both turn out thousands of cows each day and maintain the low price of beef in the United States. Plants offer salaries that are, in the world of agricultural labor, relatively high. No English is required, and the plants offer English classes and health benefits. Most of them are unionized. According to Muongkhot, younger workers typically use the plants as a stepping stone, a place to improve their English and move on. But, as the number of refugees coming into the United States has dropped, so has the pool of available laborers. “You have a lot of overtime,” Ryan Pennington, a linguist and the head of the Refugee Language Project in Amarillo, said. “They are constantly desperate to get more people in there.”